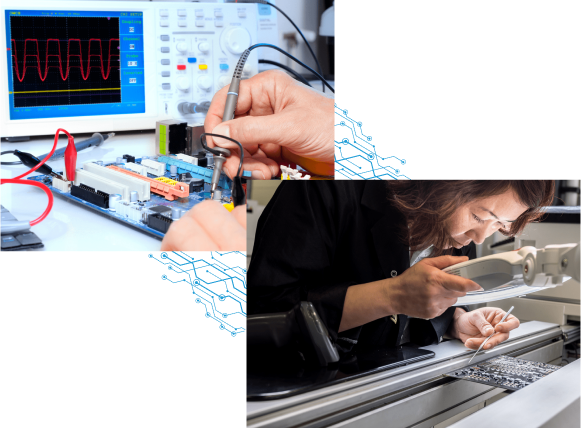

Electronics Manufacturing Testing & Inspection

Trust us to catch the problems others miss.

Bring reliable, high-performing products to market, knowing every component has been rigorously tested and inspected. Our electronics manufacturing testing expertise ensures your standards are met at every step.