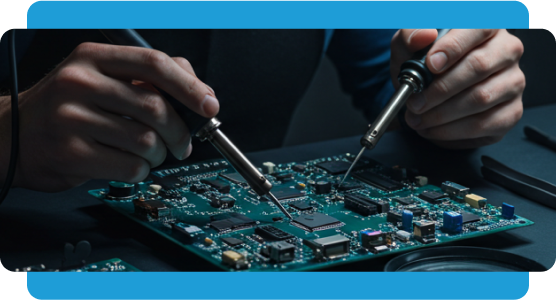

PCB Refurbishment

Extend Your Product’s Lifecycle

Revitalize your investments and shrink your carbon footprint with our electronic manufacturing refurbishment and repair services.

Revitalize your investments and shrink your carbon footprint with our electronic manufacturing refurbishment and repair services.

Replacement isn’t always the best solution when your PCB boards or electronic devices fail. Our PCB repair services help you recover damaged circuit boards, replace components, and identify broken traces—restoring performance, reducing downtime, and cutting unnecessary costs.

Whether you need warranty repair, non-warranty servicing, or large-scale refurbishment, we offer custom solutions tailored to your product’s lifecycle and operational demands.

OUR CAPABILITIES

Our expert technicians use state-of-the-art diagnostic tools to quickly identify failures, ensuring efficient repairs and minimizing downtime.

As the original manufacturer, we use high-quality components that meet original design specifications for peak reliability.

To guarantee performance, every repaired unit undergoes rigorous functional testing, dielectric testing, and AQL inspections.

Our repair and refurbishment processes meet strict industry standards, ensuring all equipment is restored to regulatory and performance requirements.

MANUFACTURING PROCESS

All incoming PCBAs undergo an initial screening to confirm failure and follow the Red Tag procedure.

If a replacement PCBA is available from inventory, it is swapped in, and the unit is retested.

If no replacement is available, the PCBA is evaluated. If it is deemed unrepairable or cost-prohibitive, it is scrapped.

Repairable PCBAs undergo troubleshooting, rework, and necessary upgrades to restore full functionality.

The repaired PCBA is retested to confirm it meets original specifications and operational requirements.

QA thoroughly inspects to ensure compliance with documented procedures and industry standards.

Repaired PCBAs are labeled “reconditioned,” assigned a new part number, and returned to inventory or shipped to the customer.

TESTIMONIALS

WHY AUGUST ELECTRONICS

Avoid costly equipment replacements—our rework services maximize the value of your existing assets.

We go beyond quick fixes, restoring your electronic device to OEM-level performance or better with high-quality components and rigorous testing.

Our barcode tracking system ensures full traceability and efficient turnaround times for PCB repairs and refurbishments.

Reduce waste and cut costs by repairing PCBs instead of replacing them—maximizing your return on investment.

Even with the best upkeep, component failure is possible. If that happens, August Electronics' expert refurbishment and repair services can restore your box build and mechanical assembly equipment to full functionality and reliability. Our structured repair process includes diagnostics, component upgrades, and thorough quality inspections to ensure your equipment meets operational standards before returning to service.

RESOURCE LIBRARY

CONTACT US

We provide repair services for printed circuit boards (PCBs), box builds, mechanical assemblies, and other electronic components designed and built by our team.

No, we only service equipment that was designed and manufactured by August Electronics. This allows us to ensure compatibility, maintain quality standards, and use OEM-grade components for optimal performance.

If August Electronics manufactured your equipment, we can assess its condition and provide a detailed evaluation. Our repair technicians determine whether a PCB repair service will restore full functionality and offer a cost-effective solution compared to buying new equipment. If damaged circuit boards can be repaired efficiently, refurbishment is often the best solution to extend the product’s lifecycle.

Yes. As the original manufacturer, we use OEM-grade PCB components to ensure electronic devices meet original design specifications.

Turnaround times depend on the complexity of the repair, replacement components, and parts availability. However, as the original manufacturer, we have direct access to electronic components, circuit boards, and populated PCBs, significantly reducing lead times.

Simply contact our team with the details, and we’ll guide you through the remanufacturing service process—from initial assessment to final testing. Our experts implement the best solution, whether PCB repair services or full electronic equipment refurbishment.

Yes! We provide preventative maintenance and servicing for the products we manufacture, helping you maximize uptime and performance in the field.

Since we built your equipment, we have an in-depth understanding of its components, software, and performance requirements. Unlike third-party providers, we use original specifications, OEM components, and advanced repair techniques to properly address issues like broken traces, solder splash, or damaged edges. We also perform rigorous quality testing to verify electrical connections and circuit board reliability before returning your equipment.

Yes! Depending on the equipment and its intended use, we can assess possible upgrades, firmware updates, and component replacements to improve performance and extend the lifecycle.

Our PCB repair services cover many printed circuit board problems, including trace damage, broken circuits, and faulty components. We also address issues like excess solder, short circuits, and electrostatic discharge damage to restore functionality to the entire circuit board.

Yes! Our in-depth repairs extend to multi-layer boards, including fixing plated through holes, replacing BGA pads, and repairing damaged edges caused by excessive heat or normal wear.

You should consider repair and refurbishment services when: