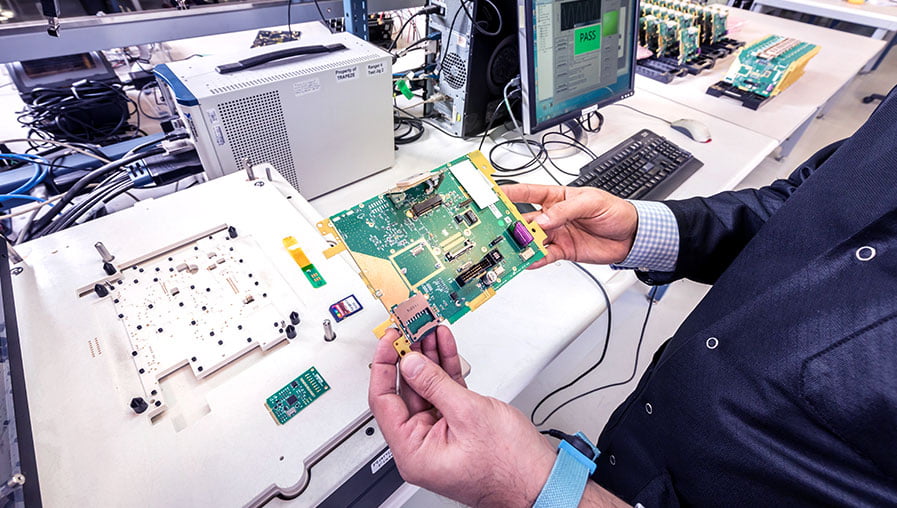

Conformal coating & encapsulation / potting

Conformal coating and encapsulation / potting provides protection to your printed circuit boards (PCB) and box build assemblies against moisture, chemicals, dust and harsh environments with extreme temperature fluctuations.

Our experienced team knows that our clients and their end-users depend on their electronic products and assemblies performing, no matter what kind of rugged environment they are in. As your strategic electronic manufacturing services provider, we recommend the best type of coating material, thickness and coverage that would be required to protect your investment.

We have our standard conformal coat process that utilizes a tri-mode dispensing head with computer controlled selectable dispensing system complete with a conveyorized UV curing oven. The conformal coating process protects your PCBs from moisture and corrosive environments by applying a clear hard coating of acrylated urethane.

Encapsulation / potting is a better option for products or assemblies requiring a more robust form of protection from moisture, corrosion and chemicals. Our standard spray and manual mask application process enables us to apply a wide variety of encapsulation materials such as epoxies and elastomers. Or alternatively, we can work with your engineering team to design and construct jigging or molds during the development of a customized encapsulation process specific to your product or assembly requirements.

To enable future serviceability, our Accuflow micro blasting station utilizes awe can selectively a mild abrasive blasting media such as ground walnut shells to remove the coating to test, repair or upgrade your PCBs and assemblies.