Design for Manufacturability in Contract Electronics Manufacturing: A Comprehensive Guide

Introduction

In the fast-paced realm of electronics manufacturing, ensuring designs are efficient, cost-effective, and of the highest quality is crucial. This is where Design for Manufacturability (DFM) comes into play. By integrating DFM principles, companies can significantly enhance the production process, resulting in superior products and reduced costs. Our expertise in DFM encompasses various aspects, including design for assembly, inspection, costing, and testing. This article delves into the intricacies of DFM, showcasing how it transforms production processes and offers substantial value-added benefits.

The Importance of Design for Manufacturability (DFM)

Design for Manufacturability is a critical process in the production cycle, aiming to simplify the manufacturing process, reduce costs, and improve product quality. By integrating a DFM partner or principles early in the design phase allows manufacturers to identify potential issues and inefficiencies that could arise during production. This proactive approach leads to significant cost savings, enhanced quality, and faster time-to-market for products.

Custom Electronic Design for Manufacturability & Assembly

At August Electronics, we offer custom DFM solutions tailored to our partners’ specific needs. Our strategic partnership with clients begins with design for manufacturability during the New Product Introduction stage. This includes:

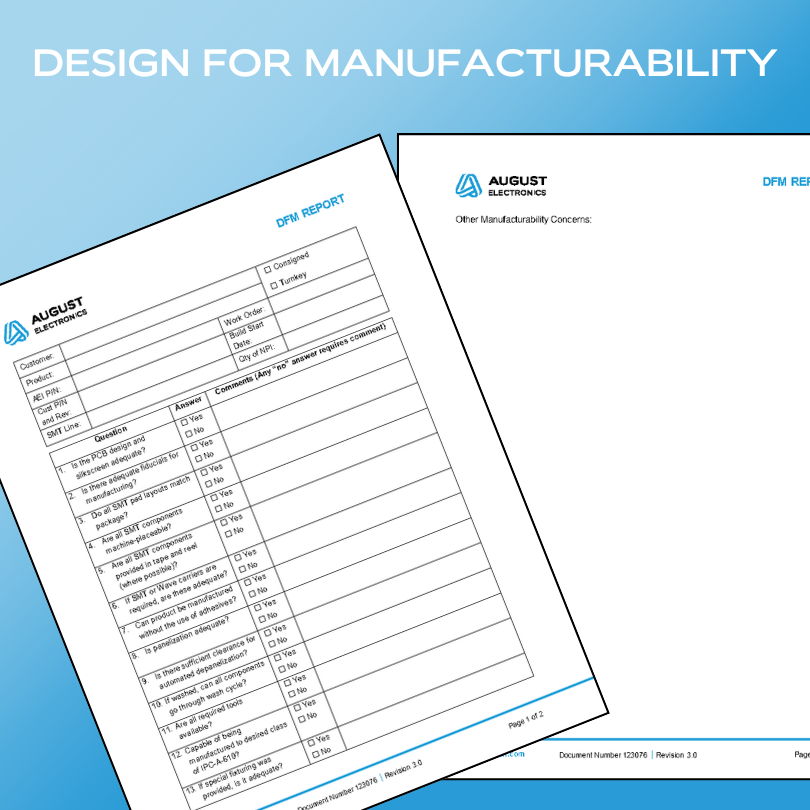

Design for Assembly (DFA) focuses on simplifying product assembly, reducing the number of parts, and minimizing the assembly steps. This approach not only decreases assembly time but also reduces the potential for errors. By designing products with assembly in mind, manufacturers can achieve higher production efficiency and lower costs. Our customized DFM reports verify the Bill of Materials (BOM) against our review, capturing valuable savings and streamlining the production process.

Design for Inspection (DFI) ensures product designs are conducive to inspection and is vital for maintaining quality. Design for Inspection (DFI) involves creating designs that are easy to inspect, allowing for quick identification of defects and ensuring that products meet quality standards. This process helps in maintaining consistency and reliability in the final products.

Design for Costing (DFC) aims to optimize product designs to minimize production costs. By carefully selecting materials, components, and processes, manufacturers can reduce costs without compromising quality. This approach involves evaluating various cost factors and making informed decisions to achieve cost-effective production.

Design for Testing (DFT) ensures that products can be easily and efficiently tested to verify their functionality and performance. This involves designing products with testing in mind, incorporating features that facilitate testing processes. Effective DFT can reduce testing time, improve product reliability, and ensure that products meet performance standards.

Optimizing Production for Cost-Efficiency

Design for Manufacturing becomes increasingly important in medium-to-high volume production and low-volume environments. By identifying and rectifying inefficiencies early in the design process, manufacturers can streamline production, reduce non-recurring engineering (NRE) costs, and achieve cost-efficient manufacturing.

Global Market Competitiveness

In today’s global marketplace, cost, quality, and speed to market are key success factors for any product. Design for Manufacturing plays a crucial role in achieving these objectives. By optimizing designs for manufacturability, companies can produce high-quality products at lower costs and deliver them to market faster, gaining a competitive edge.

Reducing Manual Labor and Manufacturing Costs

A key goal of DFM is to minimize the amount of manual labor required in the manufacturing process. By simplifying designs and incorporating automation-friendly features, manufacturers can then reduce labor costs and improve production efficiency. This approach not only lowers manufacturing costs but also enhances product quality and consistency.

Comprehensive Manufacturing Solutions

August Electronics applies DFM principles across all manufacturing needs, including:

- Surface mount or through-hole PCB assemblies

- Box build assemblies

- Cable harness assemblies

- Electromechanical builds

- Large-scale industrial equipment

By leveraging our expertise in these areas, we ensure that products are designed for optimal manufacturability, resulting in cost-effective and high-quality production.

New Product Introduction (NPI) and Design for Manufacturability

The success of any New Product Introduction (NPI) program relies on strategic component selection, placement, and supplier choices. By integrating DFM principles, manufacturers can optimize the production process for new products, ensuring their viability and cost-efficiency throughout their lifecycle.

August Electronics provides us with PCBA population and pilot builds through their NPI program. They are incredibly flexible to work with and are very quick to respond, no matter what stage of production we are at. We enjoy working with August’s team of experts because they are friendly, collaborative and conduct themselves with a high level of professionalism. We value August’s commitment to quality and customer satisfaction in addition to their comprehensive electronic manufacturing services. Since partnering with August Electronics, we have realized the benefit from their Design for Manufacturability feedback and continual improvement processes.

Senior Buyer, Consumer Sports Performance Electronics Company

Expertise in Various Domains

Our expertise in design for manufacturing spans across electronic, mechanical, electrical, instrumentation, and electromechanical areas. This broad knowledge base enables us to provide comprehensive support and advice at critical stages of product development, ensuring successful manufacturing outcomes.

Value-Added Benefits of DFM

Our customized DFM analysis report offers measurable advantages, including:

- Optimization of Design: Improving component placement and enabling greater automation.

- Global Network: Access to a wide range of inventory options.

- Shorter Manufacturing Time: Streamlined processes and strong operating procedures.

- Enhanced Quality and Reliability: Continuous process reviews and quality control measures.

- Reduced Manufacturing Issues: Effective testing programs and supplier conformance.

Conclusion

Design for Manufacturability is a cornerstone of efficient and cost-effective production in the electronics manufacturing industry. At August Electronics, we leverage our expertise in DFM to provide our clients with superior manufacturing solutions that enhance product quality, reduce costs, and ensure timely delivery. By focusing on DFM principles, we help our clients achieve their production goals and maintain a competitive edge in the global market.

By incorporating Design for Manufacturability principles, August Electronics ensures that every product we manufacture meets the highest standards of quality, cost-efficiency, and reliability. Partner with us to optimize your production processes and achieve your manufacturing goals.

FAQs

What is Design for Manufacturability (DFM)?

Design for Manufacturability (DFM) is the process of designing products in a way that simplifies manufacturing, reduces costs, and improves quality. It involves optimizing designs to identify and rectify potential production issues early in the design phase.

Why is DFM important in electronics manufacturing?

DFM is crucial in electronics manufacturing because it helps reduce production costs, improve product quality, and ensure timely delivery. By integrating DFM principles, manufacturers can streamline production processes, minimize errors, and achieve cost-efficient manufacturing.

How does Design for Assembly (DFA) benefit the manufacturing process?

Design for Assembly (DFA) simplifies the assembly process by reducing the number of parts and minimizing assembly steps. This approach decreases assembly time, reduces potential errors, and enhances production efficiency.

What are the key components of a DFM analysis report?

A DFM analysis report typically includes recommendations for design optimization, component placement, material selection, and process improvements. It identifies potential cost overruns, duplication of components, and inefficiencies in the production process.

How does August Electronics implement DFM principles?

At August Electronics, we integrate DFM principles across all manufacturing needs, from PCB assemblies to large-scale industrial equipment. Our customized DFM reports and strategic partnerships with clients ensure optimal manufacturability, cost-efficiency, and high-quality production.

What are the advantages of partnering with August Electronics for contract manufacturing?

Partnering with August Electronics offers several advantages, including shorter manufacturing times, enhanced product quality and reliability, reduced manufacturing costs, and access to a global network of inventory options. Our expertise in DFM ensures efficient and cost-effective production for our clients.