Actively managed inventory

Every client has their own unique requirements when they are looking to partner with an EMS provider. That’s why we have both consigned and turnkey inventory management.

A streamlined and accurate inventory management system is critical to our electronic manufacturing services and surface mount technology (SMT) manufacturing operations. That is why we maintain more than 25,000 unique part numbers, each supported by source control documentation and locked down by a rigorous Engineering Change (EC) control process. Our Incoming Quality Control (IQC) process monitors all incoming parts and performs regular cycle counts.

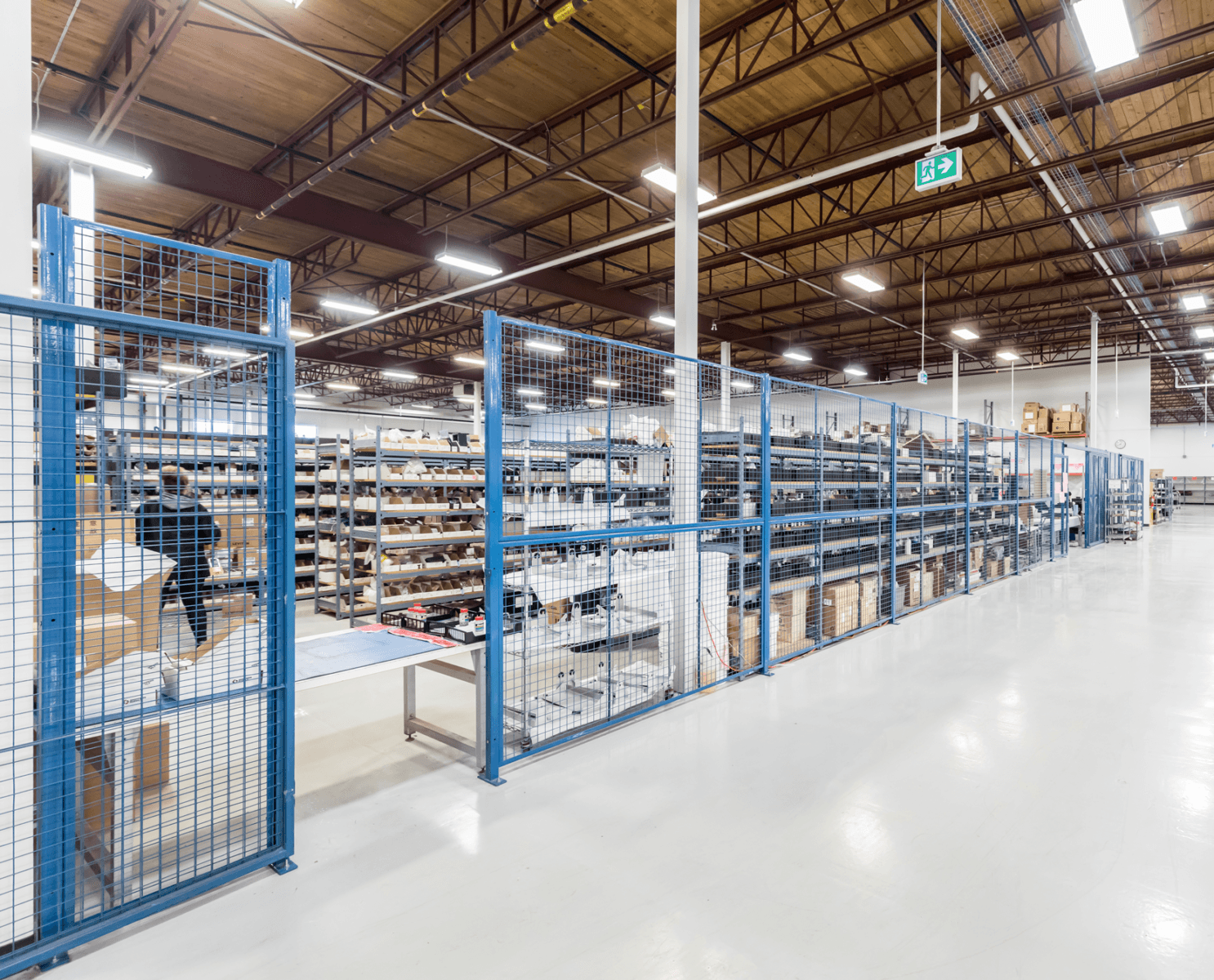

We maintain the integrity of our raw material inventory throughout the manufacturing process — by secure and proper storage, positive identification, and strict environmental controls for electrostatic discharge (ESD) and moisture sensitive device (MSD) components.

You also benefit from our efficient management of your consigned inventory. We can accommodate secure and segregated storage of your inventory within our facility for quick and easy access. Our processes for kit verification and shortage reporting give you an accurate and real-time statement of your inventory.