Cable Assembly Manufacturers

Specialty Cables Built for Reliability and Performance

High-quality, custom cable assembly solutions designed for seamless integration into box builds and mechanical assemblies.

Specialty Cables Built for Reliability and Performance

High-quality, custom cable assembly solutions designed for seamless integration into box builds and mechanical assemblies.

August Electronics is here to bring your innovative designs to life with custom cable assemblies that ensure reliable power and signal flow within your products. We are a one-stop-shop solution for your manufacturing needs.

Our cable assemblies are typically designed to be integrated into larger systems, providing reliable connections where they matter most. Whether for telecommunications, automotive, or industrial automation, we offer solutions that enhance your finished products’ overall functionality and reliability.

OUR CAPABILITIES

We produce specialty cables for demanding applications, such as medical devices, aerospace systems, renewable energy installations, and robotics. These cables can be engineered to endure extreme conditions, including harsh weather, mechanical stress, and high temperatures.

Our custom cable harnesses ensure efficient, organized, and reliable connections for complex electrical systems. We craft each harness to meet specific project needs, simplifying installation while ensuring long-lasting and secure connectivity.

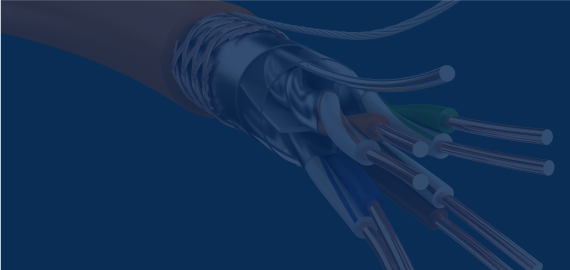

We manufacture multi-conductor cables with multiple signals or power channels within a single assembly. These cables are ideal for projects requiring efficient space utilization and effective power or data distribution, making them suitable for various complex applications.

Our shielded cables are built to maintain signal integrity by reducing noise and electromagnetic interference. These assemblies ensure reliable electrical performance in environments where signal quality is crucial, such as telecommunications and industrial automation.

MANUFACTURING PROCESS

We begin by thoroughly reviewing project requirements and specifications. This ensures that every cable assembly meets your specific requirements. Our collaborative approach means any potential challenges are identified early, resulting in a streamlined, efficient process.

We source high-quality components from trusted suppliers who meet our strict standards. This guarantees that all materials used in your cable assembly contribute to superior durability, electrical integrity, and long-term reliability, regardless of application.

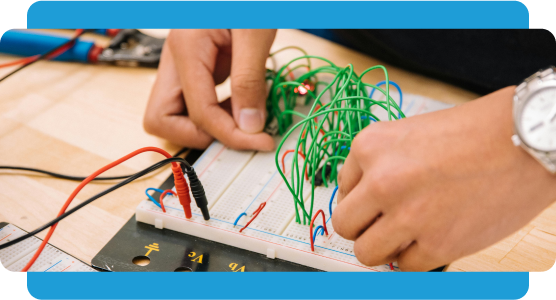

We cut and strip cables to exact lengths using advanced automated equipment, minimizing variability. This makes integrating our cables into your final product easier.

Our technicians use precision crimping technology to crimp terminals onto the ends of the wires. This step ensures secure electrical connections, which are crucial for reliable performance in the field. Proper crimping reduces the risk of failure, even in environments with high vibration or mechanical stress.

After crimping, we assemble and configure cables according to your project needs. Our team adapts to a variety of cable types and connector styles, ensuring compatibility with your specific systems. Each assembly is customized to achieve optimal fit and performance for your end product.

Each cable assembly undergoes extensive testing, including pull strength tests, continuity checks, and visual inspections. Our testing methods ensure that every connection is secure and that each assembly meets the highest performance standards required for specialized environments like medical equipment and aerospace applications.

After completing the testing process, our quality control specialists conduct a final inspection to verify that each cable assembly meets our stringent standards. Once approved, the assemblies can be integrated into larger systems, such as box builds or mechanical assemblies.

TESTIMONIALS

WHY AUGUST ELECTRONICS

Our cable assemblies are designed with a deep understanding of their role within larger systems. This ensures seamless integration and reliable performance, no matter the scale or complexity of the project. Our goal is to minimize integration issues and help accelerate your project timelines.

We excel in providing specialty cable assemblies, which distinguishes us from standard providers. This focus allows us to meet complex requirements with precision, offering tailored solutions that help our clients achieve their goals. Our decades of knowledge and expertise mean we can overcome challenges that other cable providers can't handle.

Our manufacturing facility based in North America offers high-quality assemblies with reduced lead times. Our local production allows us to collaborate closely with our clients, ensuring we meet their quality expectations and respond quickly to design changes. Being in the same region makes communication straightforward and helps us offer a more responsive, client-focused approach.

We conduct extensive testing on every assembly to ensure the highest quality and durability standards. Our commitment to quality is reflected in our adherence to industry standards, including ISO certifications, giving you the confidence that your assembly is built to last.

Our rigorous testing strategies eliminate risks and ensure your product’s reliability. Every specialty cable assembly undergoes pull strength testers and continuity checkers to verify durability and functionality.

RESOURCE LIBRARY

CONTACT US

We source our materials from trusted suppliers that adhere to stringent quality standards, ensuring the best performance for each component in our assemblies. Our sourcing process guarantees high-grade wire, connectors, terminals, and other critical materials, contributing to the durability and reliability of every cable assembly. By partnering with reputable vendors, we maintain consistency and quality in every product we manufacture.

As custom cable assembly manufacturers, we have the capacity to efficiently and precisely produce small—and large-scale cable assembly projects. Our advanced machinery and lean production methods enable us to meet mass production needs without compromising on quality. Whether your project requires a single prototype or mass production runs, we have the infrastructure to handle it.

We apply rigorous quality control processes at every stage of manufacturing. Our cable assemblies undergo comprehensive test procedures, including pull strength testing, continuity checks, and visual inspection. We also have detailed final inspections to ensure each product meets our high performance standards.

We specialize in custom wire harness solutions for various applications across industries such as telecommunications, automotive, industrial automation, and aerospace. Our wire harnesses can be designed to meet your specific project needs.