High Value Manufacturing & Six Sigma

Our VP of Manufacturing, Sara Haynes, recently completed an interview with Jeff Pallister at High Value Manufacturing for his podcast series called The Successful Manufacturing Business. Sara shares her background and experience working as a certified Six Sigma Black Belt professional in this podcast. She tells us about her journey before becoming an integral part of the August Electronics team and some electronics manufacturing industry trends.

Sara started her Six Sigma training shortly after starting her chemical Engineering career working for a traditional chemical manufacturer. She has had more of an organic career path. Her experience and skillsets, such as root cause analysis and supporting companies to overcome operational challenges, have been transferable between many different industries. Sara is a Chemical Engineer, a certified Six Sigma Black Belt and Quality Engineer, a Lean project manager, holds a Mastery of Re-Engineering, a green belt in QFD, and is certified as a Lead Auditor. She held progressive leadership positions in various companies before joining the August Electronics team.

Sara gravitated towards the Lean Six Sigma training as it involves detective work on complex manufacturing problems, determining what theories may help explain the issues observed, and testing and improving those problems. It also involves working closely with the company’s team, often making and managing organizational changes that go hand in hand with manufacturing improvements. A critical piece of Six Sigma is implementing the upgrades so that the gains stay and aren’t reverted when you stop paying attention.

Six Sigma is typically thought of and used in high-volume manufacturing environments; however, it can be applied in low to medium volume environments, such as August Electronics, but it usually depends on what type of issue you’re observing. Six Sigma often makes the most significant impact when applied across all low-volume manufactured products and not specific to one particular product. It can be a tremendous problem-solving methodology used when there is a complex problem that crosses multiple departments. Typically, when starting a Lean Six Sigma project, you would form the project team consisting of production and process staff, procurement, and subject matter experts (SMEs) from their respective departments. The role of the Black Belt is to walk the team through the Six Sigma methodology and support them in developing the solutions required to solve the problem.

A classic Six Sigma example is maximizing the manufacturing line’s utilization and reducing change over time by 80%. Once you have your project team identified, you’d start by mapping out the process and determining how the steps are performed, in addition to asking:

- what portions of the process take the most about of time?

- what are the causes of time delays?

- why do changeovers take as long as they do?

Next, you’ll need to identify what’s causing the time delays and implement solutions to decrease that time. When this time is extrapolated over multiple products over a year, you see more significant time savings.

The majority of Six Sigma project timelines take about four months to complete. Still, it largely depends on the project team’s availability and people performing the required work outside of their typical responsibilities. Six Sigma projects need to come to a close as they are intended to determine the solution and teach the employees what they need to do to support the operational changes required.

Being a low to medium volume manufacturer, August Electronics has been more focused and relies on lean manufacturing methodologies and will look to implement Six Sigma in the future. At August Electronics, Sara has implemented lean manufacturing methodologies with similar outcomes to Six Sigma, such as reducing waste, manufacturing faster, better, cheaper, reducing operational inefficiencies, and improving the overall production line flow. With electronic manufacturing margins being thin, it is always a challenge to find ways to improve, keep customers happy and continually invest in training and development for employees as well as our clients. Sara has been influential in helping our team expand, improve operational efficiency and mitigate the many challenges we’ve faced during the pandemic.

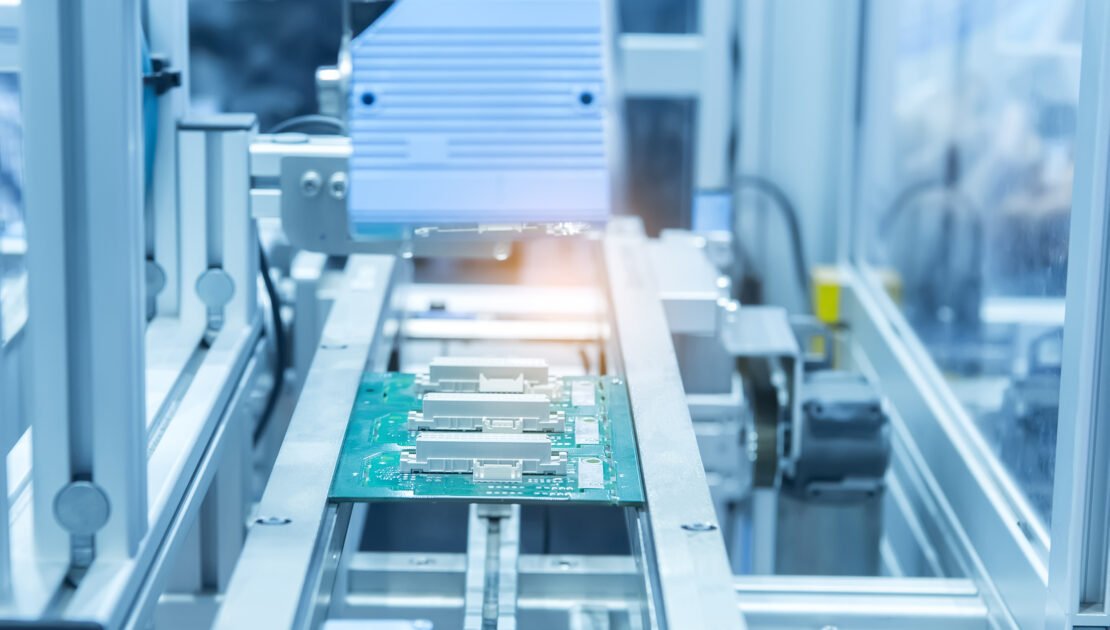

August Electronics is your partner of choice for end-to-end electronic manufacturing services. From prototyping to production, we support your entire product lifecycle. We offer a wide range of capabilities to serve your manufacturing needs including design for manufacturing, intelligent supply chain, procurement, PCB assembly, box build assembly, cable and wiring, control cabinet build & panel wiring, electro-mechanical assembly, inspection & testing services, outbound logistics, inventory management, and rework & repair. Contact us to learn more.