Start-Up Manufacturing

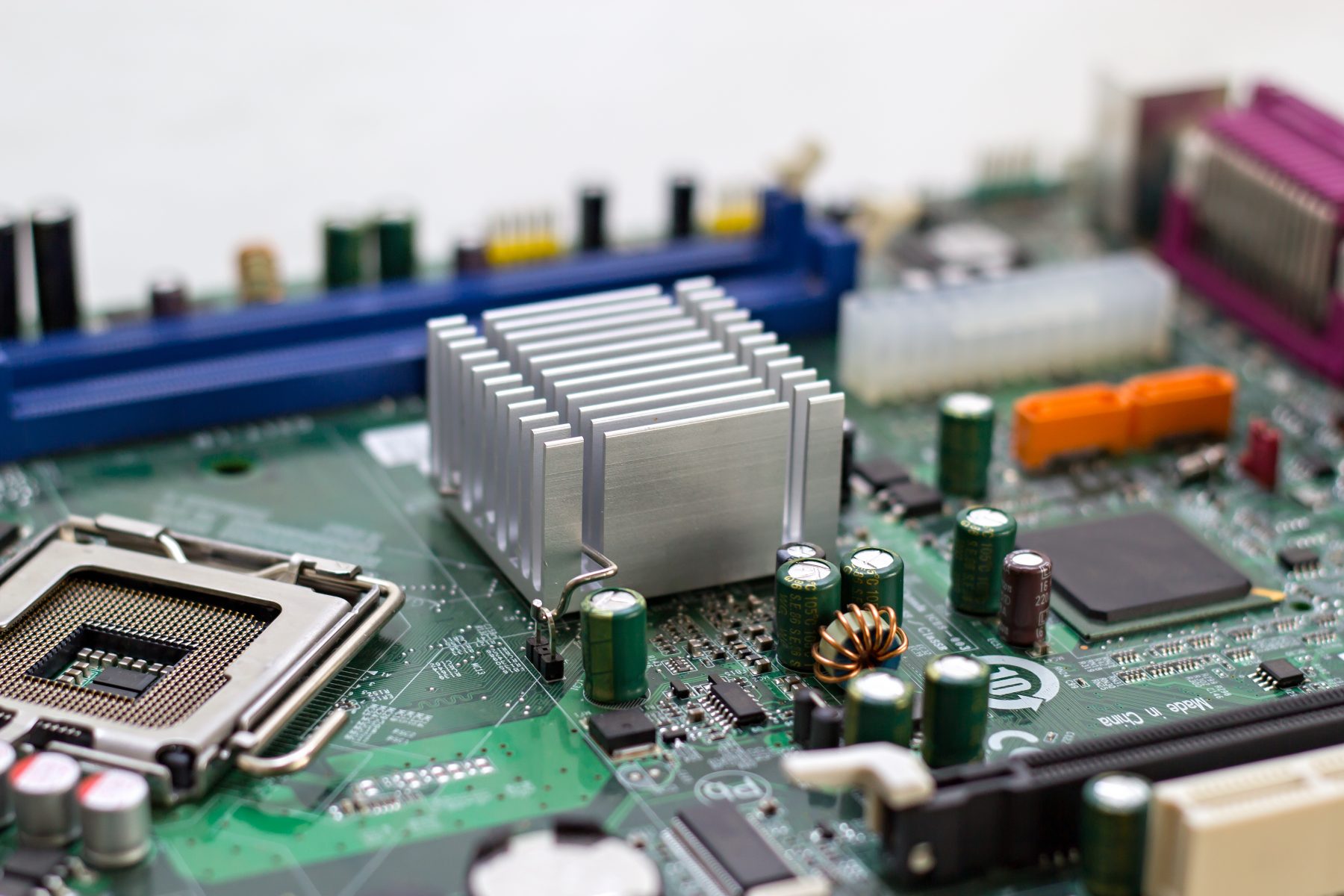

It is undeniable that innovation in nearly every industry is driven by the entrepreneurial spirit of start-ups. Identifying the right manufacturing partner with expertise, established global supply chain, and state-of-the-art facilities to convert concepts to a finished product can be challenging. Oftentimes, this indecision leads to start-ups attempting to manufacture their products in-house. While this can be a viable option, it is extremely costly and time-consuming to procure and program the appropriate equipment, determine the correct assembly, inspection and testing procedures not to mention hiring and training knowledgeable employees.

As a start-up, flexibility and the ability to adapt and adjust to various factors are especially important when selecting the right contract electronics manufacturer (CEM). You need a partner who is with you every step of your product development journey – from pilot builds to volume production and aftermarket support.