How August can help you

Our inventory management system makes it efficient to replenish your inventory while controlling costs. The lead time is significantly reduced, sometimes as short as transit times. Our diverse and accurate inventory management system is critical to our electronics manufacturing services, which is why we have more than 25,000 part numbers in stock supported by source control documentation, an Incoming Quality Control (IQC) process, a rigorous Engineering Change (EC) control process, positive identification, and strict environmental controls for ESD and MSD components.

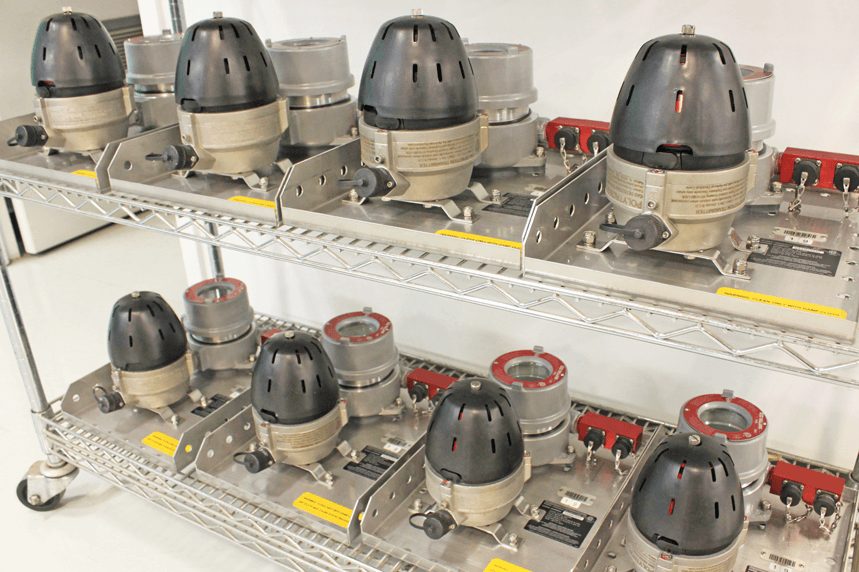

We can manage your consigned inventory in a secure and segregated storage area. Our kit verification and shortage reporting processes afford you accurate real-time statements of your inventory. We control the process by performing repairs and refurbishments in-house to revive your electronics equipment for peak and reliable field performance. We offer an automated workstation to handle in-circuit Ball Grid Arrays (BGA) and our PCB and electro-mechanical assembly experts adeptly handle manual repairs to circuit boards and final box build integrations.

We can execute your refurbishment processes or develop refurbishment standards for your field returns. Our barcode tracking for the repair process ensures traceability and consistent turnaround times.