IPCs: Shared Standards of Quality in Electronics Assembly

Manufacturing your printed circuit board assembly involves several steps. All of them demand careful attention to ensure that components, soldering, materials, finishes, processes, checks and balances are efficiently coordinated for quality control and assurance.

As an Original Equipment Manufacturer (OEM), you may generally evaluate the quality of your PCB assembly on three parameters:

- Functionality

- Long-term reliability

- Aesthetics

However, quality is a concept that means different things to different people. This is where standards come in – as a means to establish a common platform of the shared meaning of “quality”.

Relevance of IPC standards

IPC is a trade association that works to standardize assembly and production requirements for electronic equipment and their assemblies. Accredited by the American National Standards Institute (ANSI), IPC produces the most widely-recognized and applied acceptability standards in the electronics manufacturing industry.

These standards become immensely important in communicating the same meaning about what acceptable standards are – so that an OEM, its contract electronics manufacturing (CEM) partner, and the industry at large, know exactly what “acceptability” entails. With IPC standards, acceptability is not a relative concept.

IPC-A-610 provides a set of visual quality acceptability requirements for electronic assemblies. Class 2 deals with dedicated service electronic products, and Class 3 with high performance electronic products.

- Class 2 tends to be the most popular option for non-critical assemblies, where long-term reliability is a nice-to-have but not absolutely essential. Aesthetics may not be top-notch but assemblies will perform electrical and mechanical functions as they are intended to.

- Class 3 represents the highest standard where all IPC criteria will be met across process like laminates, plating thickness, materials qualification, and so forth. It is typically used for printed circuit board assemblies (PCBA) where it is critical for continued high performance or performance on demand. The end use environment for these assemblies may be uncommonly harsh, requiring the equipment to function as it should, as downtime is not an option.

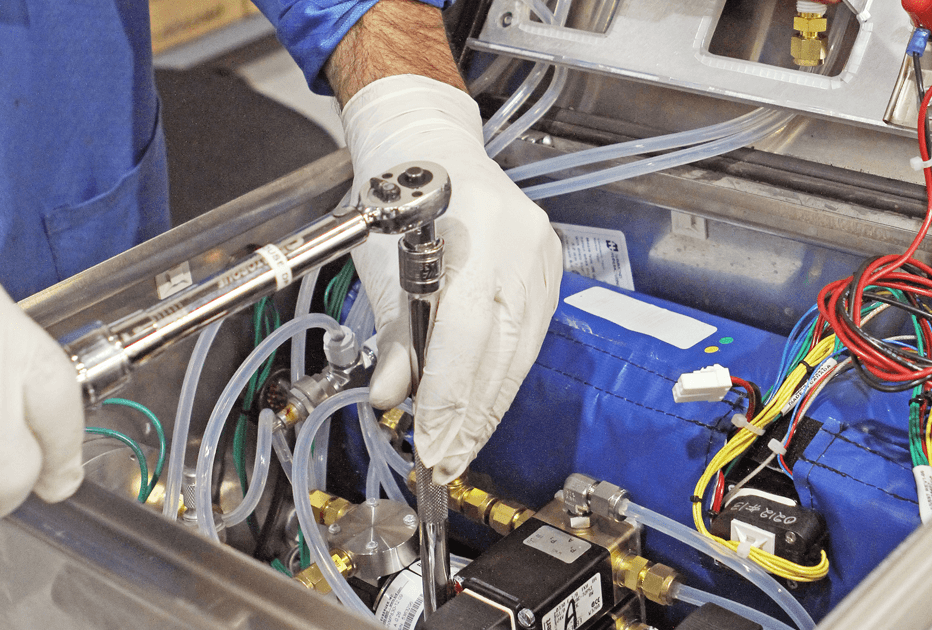

IPC-7711 sets acceptability standards for rework, repair and modifications of electronic assemblies including surface mount and through-hole rework, component removal and replacement, wire splicing, solder resist repair, modification or repair of laminate material and conductors, as well as other industry-approved techniques.

Why use an IPC-certified CEM?

OEMs benefit from using IPC-certified CEM partners by:

- Improving cross-channel communications. This ensures all stakeholders use the same terminology and adhere to the same standards. A lack of clear communication can delay or even derail production.

- Controlling end product quality, consistency and reliability throughout the manufacturing process. Better performing and longer lasting products yields profitability.

- Controlling costs or even reducing costs as consistent, replicable and streamlined manufacturing allows your products to meet stringent quality inspections and tests; minimizing the likelihood of costly delays, scrap or extensive reworking.

The August partnership

At August, we are committed to ensuring top quality, reliability and consistency of your manufactured products – which is why we have well-established quality management systems and processes.

We have invested in our own in-house IPC-certified trainer so that all our production staff are mentored, trained and certified to:

- build to IPC-A-610 Class 2 or 3; and

- restore or repair electronic assemblies to IPC-7711 Class 2 or 3.

We can work with you to help you understand the principles that guide the different classes of IPC standards – so that you have an idea of what to expect in terms of the final manufactured product.

Based on a firm grasp of these principles, you would select the IPC standard class best-suited to your products and their intended end-use.

Partnering with August Electronics enables you to leverage our well established quality processes as well as our IPC-certified technicians and systems. You can then be assured your products are manufactured to meet IPC standards in an auditable fashion.

When you consider your next contract electronics manufacturing partner, it is useful to look into their IPC credentials, so that they are able to meet your, your clients’ and the industry’s standards of quality for electronic equipment assemblies.

Need more information or just want to learn more about IPC standards? We’d love to chat, please contact us today.