Your manufacturing partner for QA/QC, Inspection & Testing

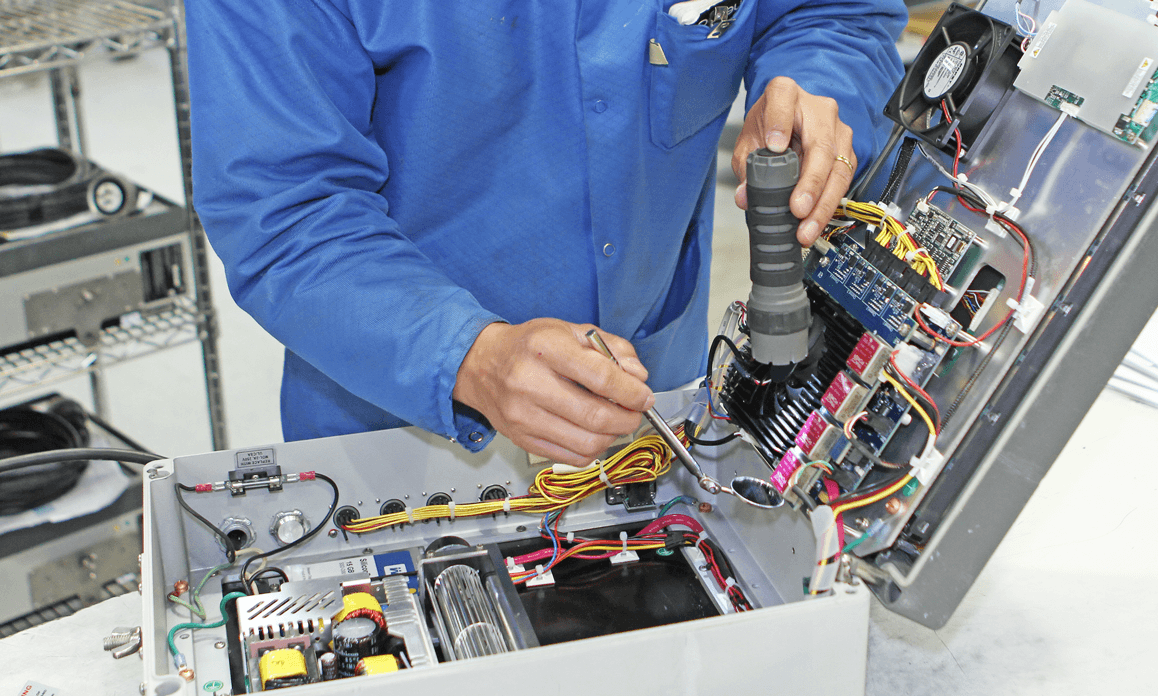

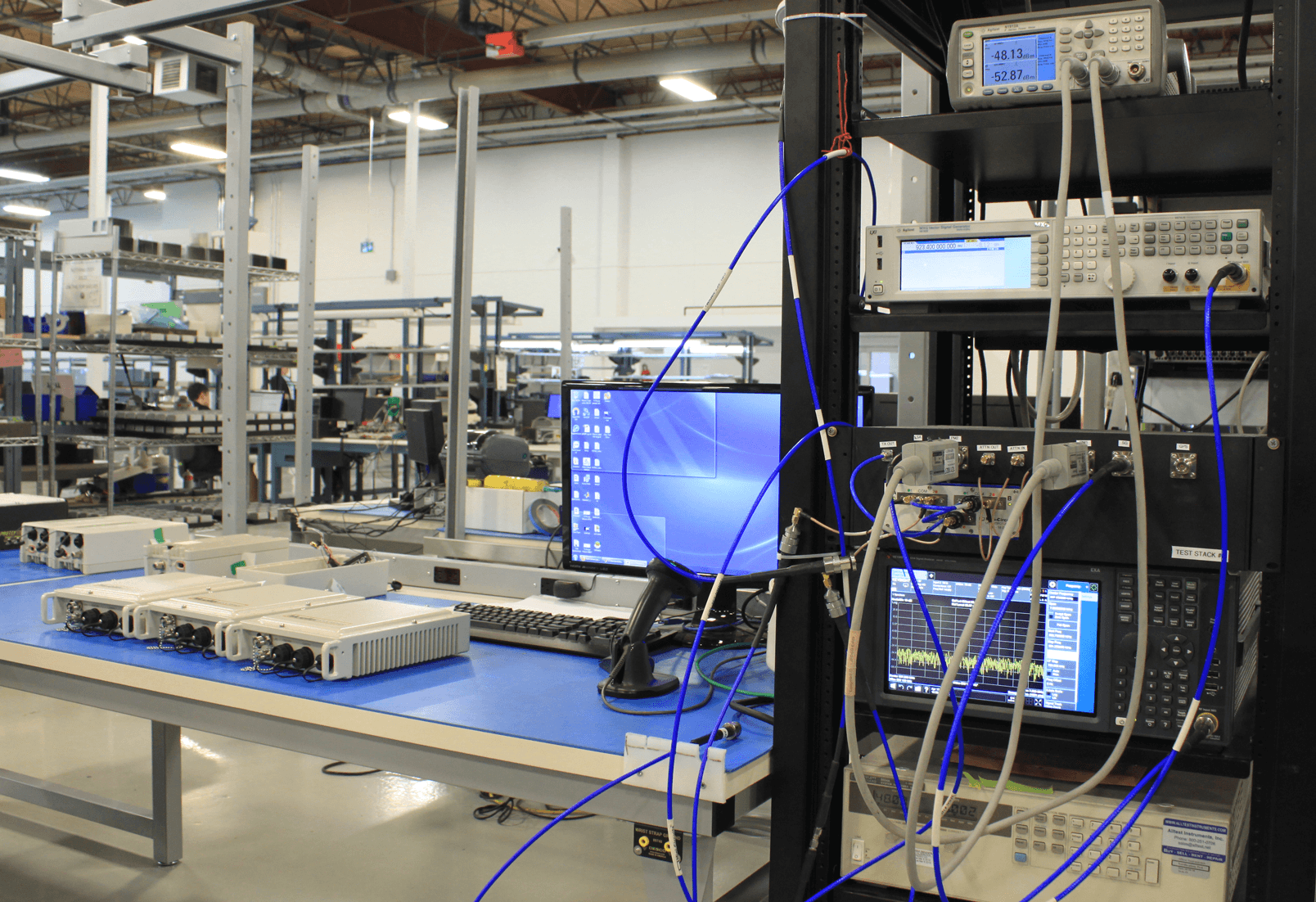

We understand that the quality of your product and the end-user experience affects your reputation. We work to troubleshoot, identify and eliminate the root cause of non-conforming materials or failures with our comprehensive quality management system. The way we achieve superior quality products and repeatable results is by utilizing a suite of inspection and testing methods for quality assurance and quality control at various manufacturing and assembly stages.

Quality is a core commitment we make to you as our valued client, and to ourselves as responsible engineers, technologists and manufacturing experts. We stand behind the products we manufacture.