EMS Strategic Planning

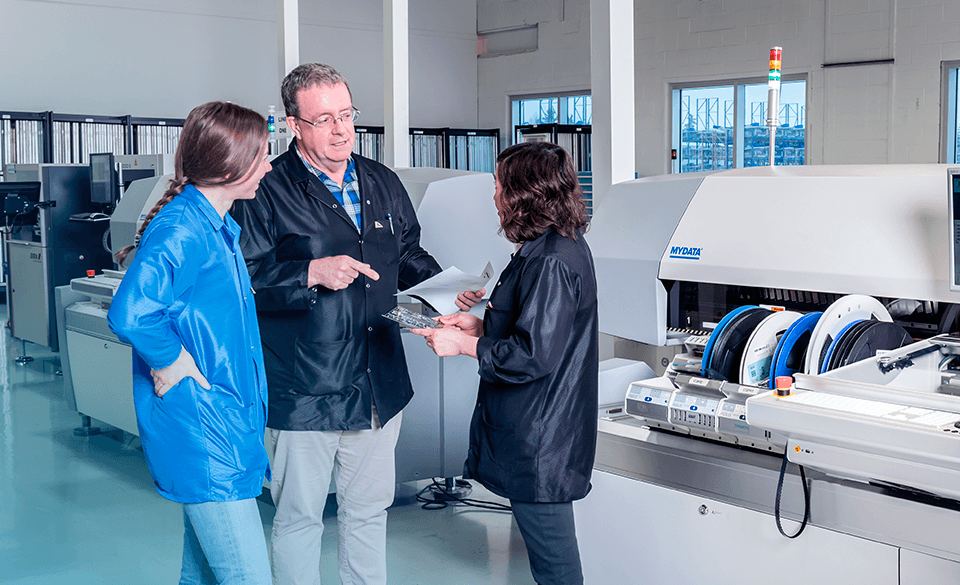

Good planning ensures optimal use of resources, materials, scheduling of manufacturing processes and labour, as well as managing the supply chain to balance demand and capacity.

This involves a strong element of anticipating needs over time. In the short term, all resources must be scheduled in detail allowing for different factors that play a role in taking a product from concept to the market based on your timelines and in the most cost-efficient manner. The right materials and inventory must be managed efficiently with accurate reporting and forecasting. Eventually leading to long term planning such as upgrading or procuring additional equipment as required to support demand of your products.