Design For Manufacturing & Assembly

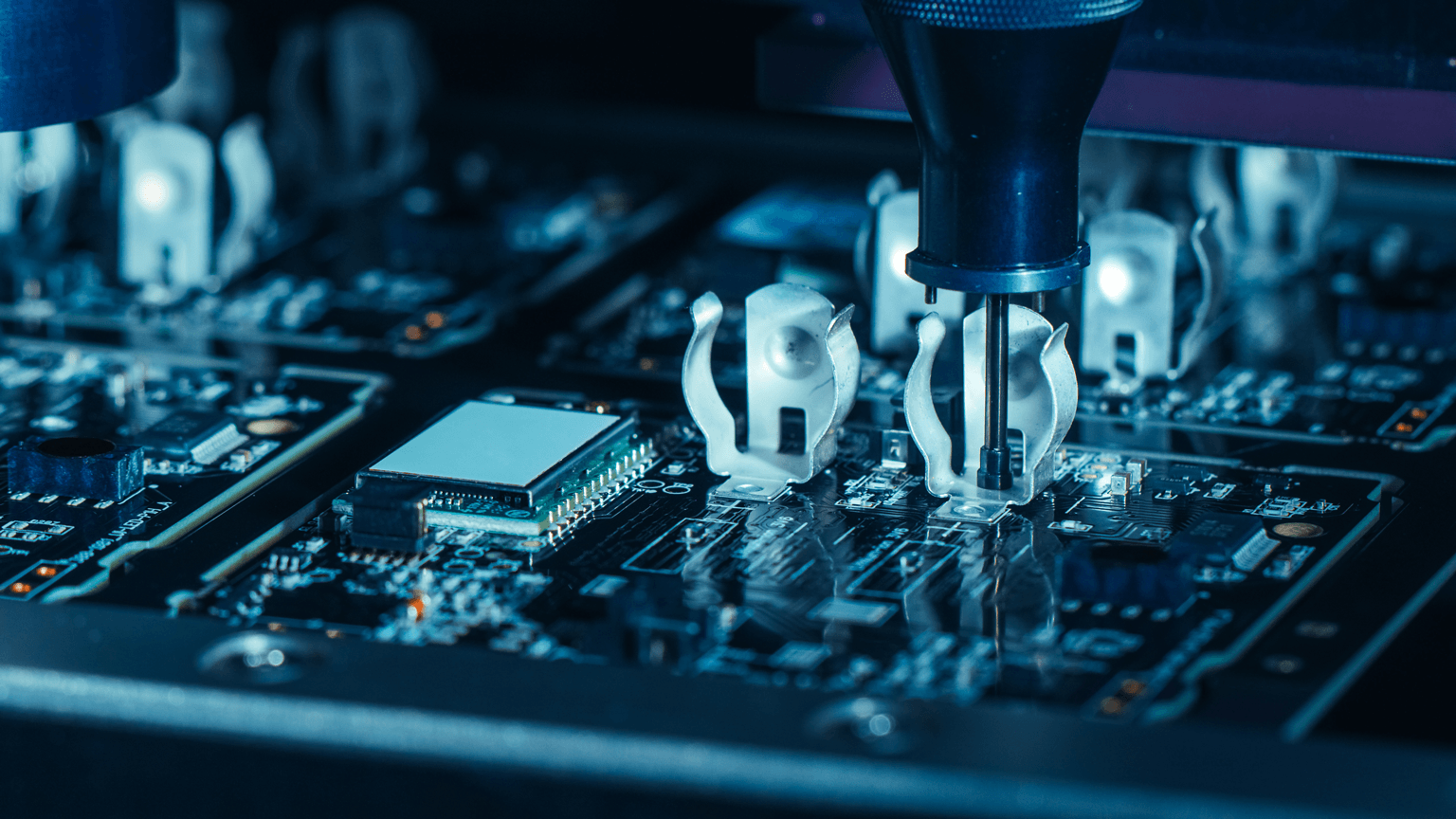

As your strategic partner through your product development cycle, we start by assisting our clients in developing the optimal design for manufacturing; which includes design for assembly (DFA), design for inspection (DFI), design for costing (DFC), and design for testing (DFT) feedback. This enables the most cost-efficient assembly of your innovation, a shorter delivery timeline where possible, and stronger quality assurance. We generate customized reports that verify your Bill of Materials against our review. This encapsulates valuable savings early in the process.

Design for manufacturing becomes increasingly important for medium to high-volume production as well as for low-volume environments where it helps to reduce non-recurring engineering (NRE).

Our design for manufacturing efforts are aimed at helping you optimize your designs of a part, assembly, process or product to be more cost-effective, to be of better quality and to meet production timelines.